Very few people taking an airline flight ever stop to consider all of the different conditions under which an airplane wing has to perform. Takeoffs, cruising at altitude, maneuvering and landing are all situations that put very different demands on aircraft wings and require different wing shapes in order to perform most efficiently. Of course an aircraft can’t change its wings in the middle of a flight so current wing designs are a compromise that with the addition of airfoils and flaps succeed in doing an adequate, if not optimal job.

Now NASA’s Ames Research Center is teaming with the Massachusetts Institute of Technology (MIT) to develop an entirely new kind of aircraft wing that can literally morph its shape while in flight. The technology is known as MADCAT or Mission Adaptive Digital Composite Aerostructure Technologies and testing is nearing completion at Ames’ wind tunnel on a four-meter wide prototype model wing. See image below.

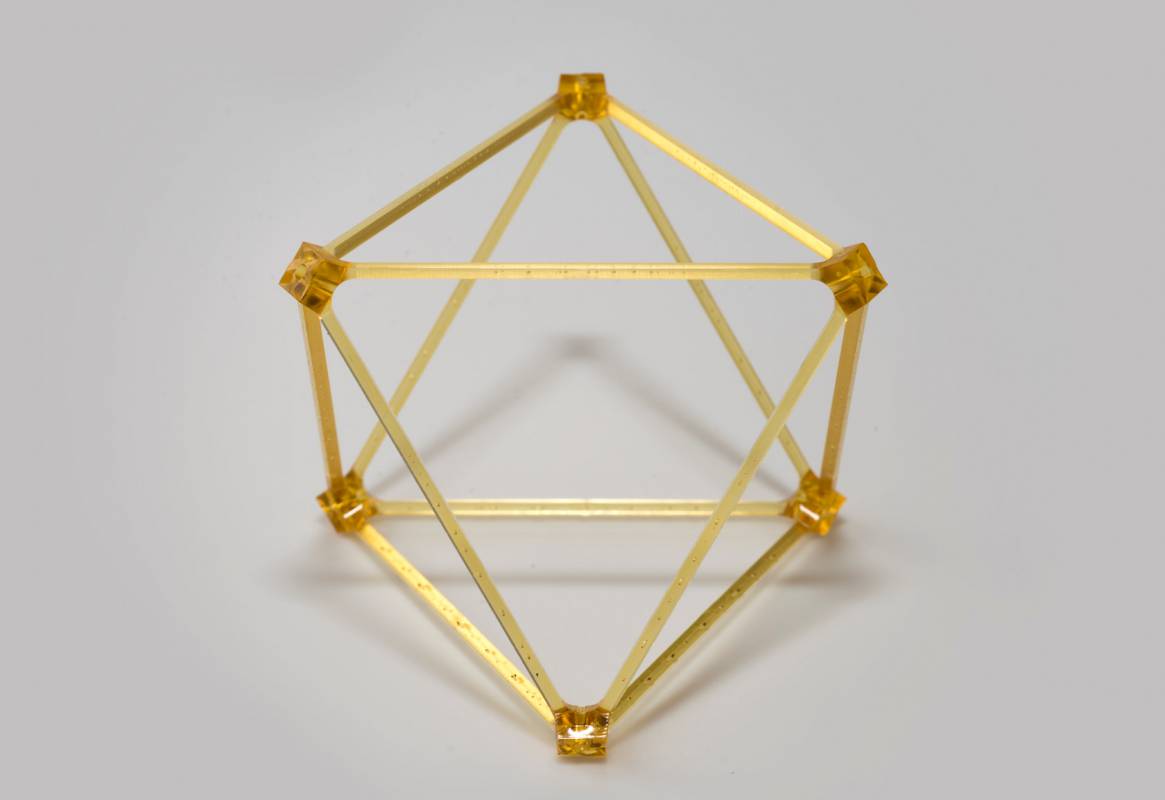

The new technology begins by constructing the wing in an entirely new, modular approach. As seen in the images below, each individual module in the design is an eight-sided octahedron composed of carbon fibers that can be formed by injection molding in only 17 seconds, making them very cheap to produce in quantity. The interior of the wing is then built up of a lattice of these modules.

The modular lattice so constructed is highly flexible and when covered with a layer of polymer material the wing can morph its shape in order to optimize its aerodynamic properties. Needless to say Computer control of every module is an essential part of the morphing process.

However a single central computer having to process the data from all the necessary sensors, which are spread over the surface of the wing, would simply take too long to make the required decisions. Therefore a distributed approach to wing control is employed so that each module can alter its shape in order for the entire wing to adapt.

Despite its complexity the MADCAT wing should actually be simpler to manufacture and repair since each module is identical. The MADCAT wing is also lighter and can be even stronger depending on the material from which it is cobstructed.

Another potential advantage to the radical new design for aircraft wings is that it may finally spur aviation companies to switch from the traditional cylindrical fuselage with wings aircraft design to an integrated body-wing design that has long been known to be more efficient. Over the last 60-70 years there have been several airplanes to have used that design, the images below are of the flying wing and B-2 stealth bomber. Aircraft manufacturers are conservative however, and rightly so given the inherent dangers of flying. In addition to safety concerns there will also be the cost of switching to an entirely new way of manufacturing airplanes.

The new MADCAT wing could be just the thing to change their minds. As you can see from the first image at the top, the modular wing approach is just perfect for a flying wing airplane design and the tremendous increase in efficiency the combination would provide could be more than aerospace companies can resist.

The future looks bright for MADCAT but there could be a long way to go before you will be flying anywhere on a morphing wing airplane.