The image we all have of robots, provided courtesy of sci-fi movies of course, is that of a hard metallic body and limbs with a basically human shape. After all humans have been using metals for a long time and of course we’re quite familiar with how to use our own body shape and limbs in order to get things done. So it’s understandable that the industrial robots that have been developed over the last few decades would resemble metal and plastic versions of our own body parts.

Other creatures have other ways of doing things however and quite often their way is better than ours. Robotic engineers have started to realize the advantages that these alternate ways of moving and manipulating can provide to their designs. At the same time they are also beginning to employ different materials in the construction of their robots. Together these new technologies are known as soft robots or biohybrid robots and they’re gaining a lot of attention as they begin to accomplish tasks that other robots found to be difficult or even impossible.

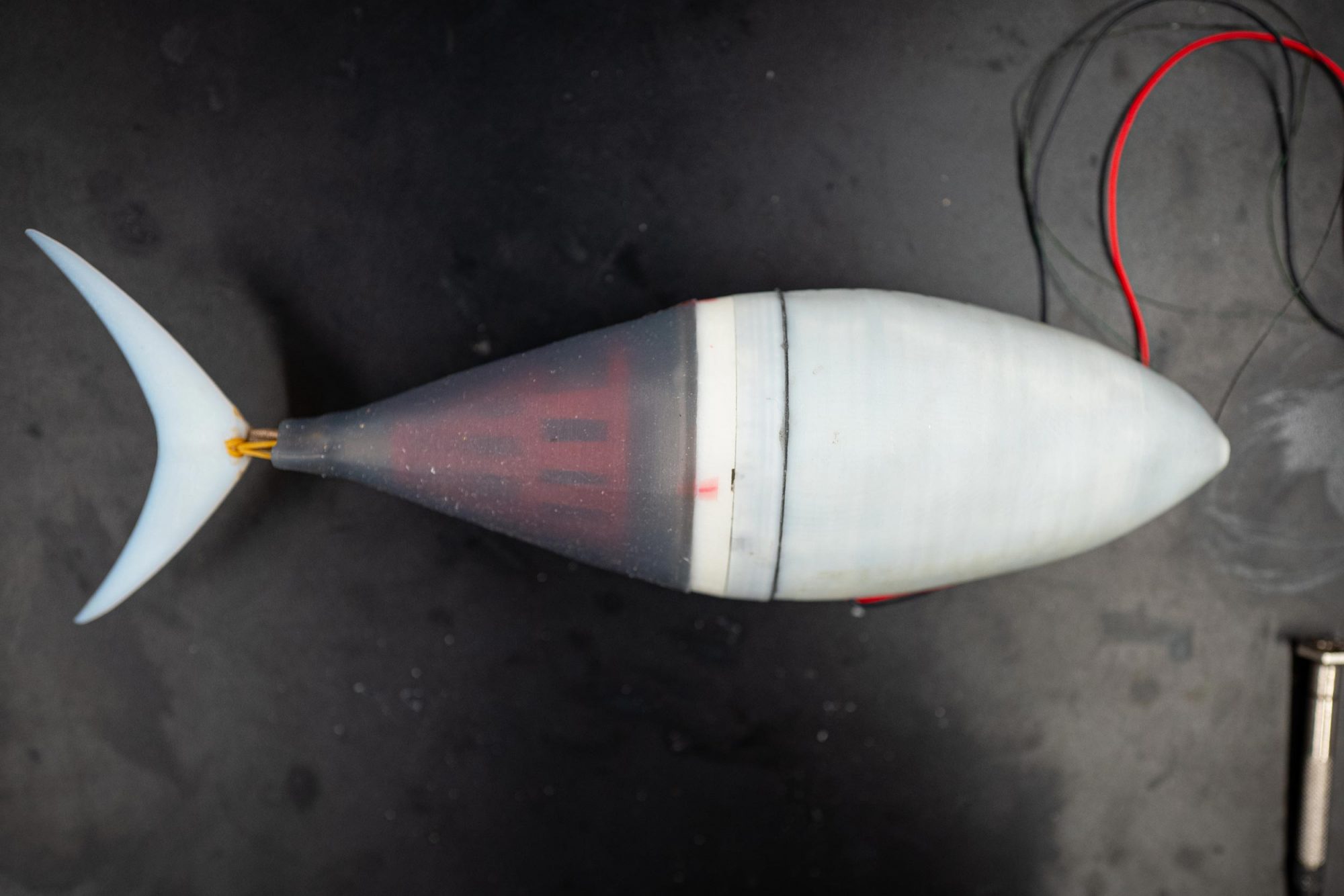

Swimming is one activity that we all realize that humans aren’t really designed for, so the idea of designed a swimming robot to resemble a fish makes a lot of sense. It’s not surprising then that researchers at the University of Virginia’s School of Engineering are developing a robot based upon the anatomy of one of the ocean’s fastest and most efficient swimmers, they call it Tunabot.

Led by Professor Hilary Bart-Smith Tunabot has been funded by the U. S. Navy with the goal to not only design and develop a robot that mimics the swimming behavior of a yellowfin tuna but to use that robot as a platform to better understand alternative forms of propulsion. Tunabot itself is an eyeless, tailfin only model some 25cm in length whose swimming prowess can be measured in a test tank at the Mechanical and Aerospace Engineering at UVA. With its tail beating at the same rate as a yellowfin does in the wild Tunabot is capable of producing a propulsive force nearly equivalent to that of its natural counterpart.

The development of Tunabot is only the start of the research program however. “We don’t assume that biology has evolved the best solution.” Professor Bart-Smith says. “Our Ultimate goal is to surpass biology. How can we build something that looks like biology but swims faster than anything you see out there in the Ocean?”

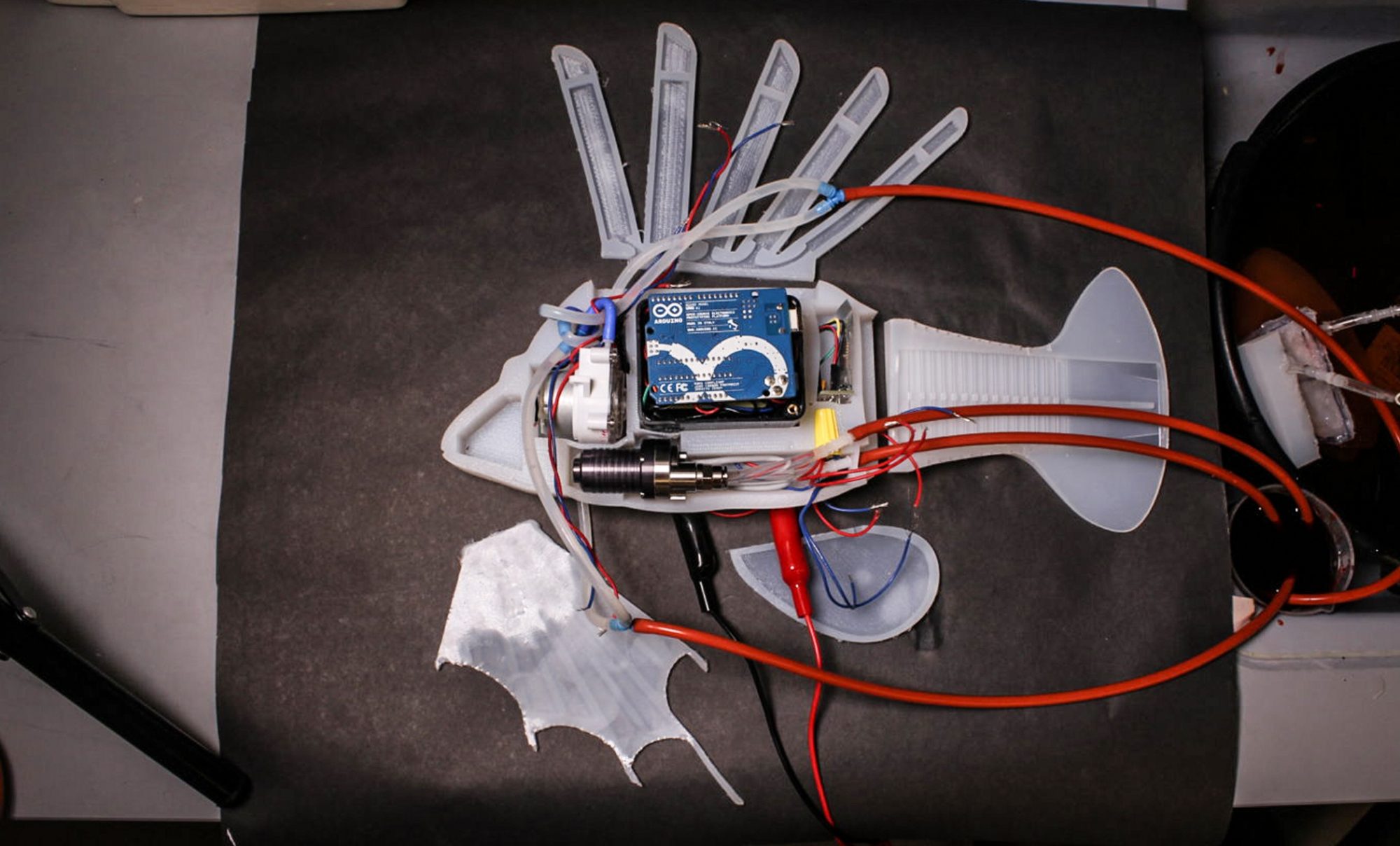

Another team of researchers at Cornell and the University of Pennsylvania are also developing a robotic fish as their test platform for a radical new technique that can both power and propel their robot, ‘artificial blood’. You see the robot, which is designed to resemble a lionfish, see image below and my post of the 18th of April 2019, uses a pressurized fluid to activate motors in its tail and pectoral fins that enable it to move through the water.

Such hydraulic systems are quite common in robots but here its only half the story because the fluid is also an ionized electrolyte solution that stores the energy needed to power the robot. As the electrolyte flows around the robot it passes through electric cells that use the ions to produce a voltage that powers the pumps that keep the fluid pressurized! This whole integrated approach is very similar to how our blood does provide the energy that enables our muscles to move.

At the present time the robot lionfish moves rather slowly but it can keep moving for 36 hours. The engineers, led by Cornell Professor Robert Shepard, are hard at work on increasing the energy density of the system that will increase the robots speed. One advantage of the technique is that since their battery is a fluid it can easily be fitted into any spare space in the design increasing the total amount of energy contained within the robot.

Even though this technology is in its infancy the integration of energy storage and hydraulic force into a single fluid offers a great deal of promise. Living creatures have evolved over billions of years to make multiple uses of their body parts and now it seems that engineers are learning to follow the same paradigm.

Another ocean dweller whose lifestyle is so different from ours that engineers are intrigued by the possibility of it teaching them new ways to manipulate objects is the octopus. These intelligent invertebrates are well known for both the strength and delicacy of their many tentacles, attributes that engineers would like to emulate.

Cecilia Laschi at the Sant’Anna School for Advanced studies in Pisa Italy has succeeded in constructing a robotic octopus’s tentacle capable of behaving in a very lifelike fashion, undulating, elongating, curling and stiffening as required. The tentacle’s movements are created by an array of springs and metal cables; some composed of shaped memory alloys that will return to a predetermined shape when heated.

Laschi is currently developing a compete robot octopus and has already developed a propulsion system based on the octopus’s jet. “When I started with the octopus, people asked me what it was for,” Laschi says. “I don’t know, but I’m sure if it succeeds there could be many applications.” Soft robots in general are finding more and more applications as engineers look more and more to nature for inspiration for innovation designs.