The idea behind lab-grown or cultured meat is actually quite simple. First you extract a few cells from a tasty region of an animal’s body, let’s say the prime rib area of a cow or a chicken’s breast. Just a few cells, not enough to harm the animal. Then you grow those cells in the lab, billions of them, enough to make them into beefsteaks and chicken breasts or other cuts of meat that you can then sell as food to your customers.

There are several advantages to producing meat in the lab. First of all you don’t have to waste energy and materials producing the non-eatable parts of the animal, like bones and skin. In fact you don’t even have to produce the less popular cuts of meat like the brains or intestines. Then there’s hygiene and quality control. Meat produced in the lab is less likely to be infected with bacteria or absorb toxic chemicals like mercury from the environment.

Then there’s the morality aspect. Cultured meat doesn’t require the death, or indeed any real harm to the animal who supplied the original small number of cells that started the whole process. In today’s world there are many people who are concerned about the welfare of the animals we raise and slaughter to feed ourselves. Lab grown meat would require far fewer animals, who would probably be given far better living conditions in order that they produce the best possible cells, and aside from an occasional biopsy to procure some of those cells they would never be harmed. In other words ethical treatment of animals!

Sounds crazy but it’s actually been done. In my post of 7 April 2018 I reported on the first ever cooking of a hamburger made from lab grown meat back in 2013. Those few reporters who were granted a taste of that burger pronounced it to be tasty, but rather dry and a bit too tough.

That’s been the trouble so far, texture and juiciness. You see the meat we buy in a supermarket, the meat that comes from a once-living animal, is more than just muscle cells. There are also fat cells as well and not only is the ratio of muscle to fat cells important to get a nice juicy meat but the two distinct kinds of cells have to be ‘assembled’ in a way that mimics the texture of naturally produced meat.

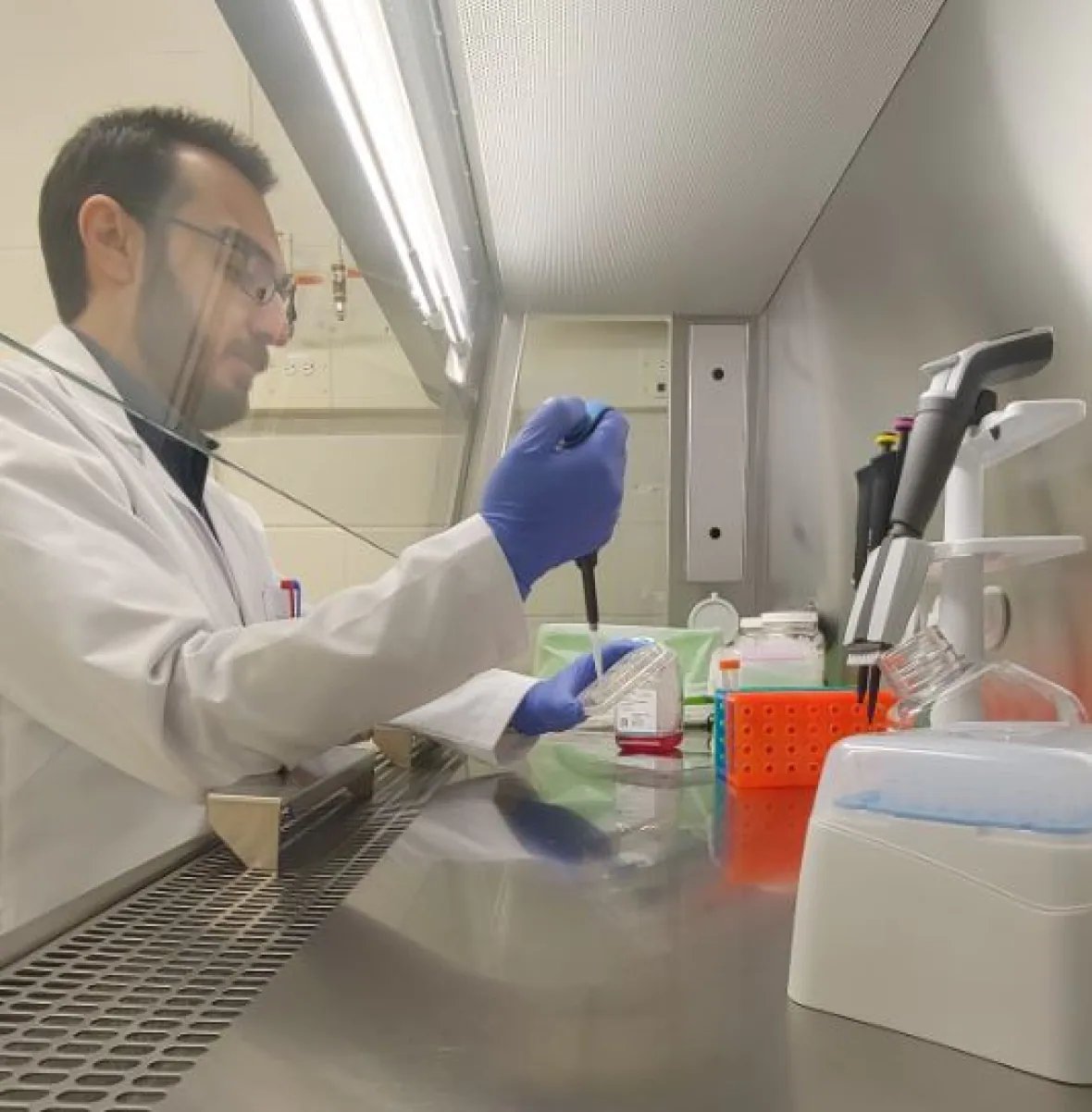

A pair of researchers at McMaster University in Canada’s Department of Biomedical Engineering have been working on that problem. Starting with a technique that produces thin sheets of living tissue in a nutrient solution for human transplants (See my post of 16 May 2020) Ravi Selvaganapathy and Alireza Shahin-Shamsabadi succeeded in stacking those sheets of muscle and fat cells. Each of those sheets has a thickness about that of a sheet of printer paper and when stacked together the cells would begin to bond to each other spontaneously.

The initial experiments were carried out with cells gathered from labouratory mice but the researchers decided not to sample their ‘mouse steak’. Instead Selvaganapathy and Shahin-Shamsabadi performed a second experiment with rabbit cells with a result that Selvaganapathy proclaimed. “It felt and tasted just like meat.”

One advantage of Selvaganapathy and Shahin-Shamsabadi’s technique is that the muscle / fat ratio can be varied quite precisely to match the desires of potential customers. The researchers are convinced that their technique will work equally as well for a range of other meats, beef, pork and chicken being obvious choices. Personally I’m curious as to whether the technique would work as well for fish, like a nice salmon or tuna fillet.

Selvaganapathy and Shahin-Shamsabadi are now hoping to increase the scale of production. They’ve formed a start-up company to explore the commercial possibilities of their process. They certainly have a good marketing slogan that they can use. “Real Meat built to Order.” They may have to get used to some competition however, there are at least 38 different companies seeking to gain a foothold in what could soon be a very profitable industry.

Food production in general is poised to undergo a revolution during the 21st century. Whether it be aquaculture or urban farming or cultured meat the way we produce our food in thirty to fifty years from now is going to look nothing like the farms and ranches where food has been grown for the past ten thousand years. It has to change because those old ways of agriculture are unsustainable in a world of eight billion or more human beings.